Uses a mold of sand packed around a

polystyrene foam pattern which vaporizes when molten metal is poured into

mold

§Other

names: lost‑foam process, lost pattern process, evaporative‑foam process, and

full‑mold process

§Polystyrene

foam pattern includes sprue, risers, gating system, and internal

cores (if needed)

§Mold

does not have to be opened into cope and drag sections

Figure

Expanded polystyrene casting process: pattern

of polystyrene is coated with refractory compound;

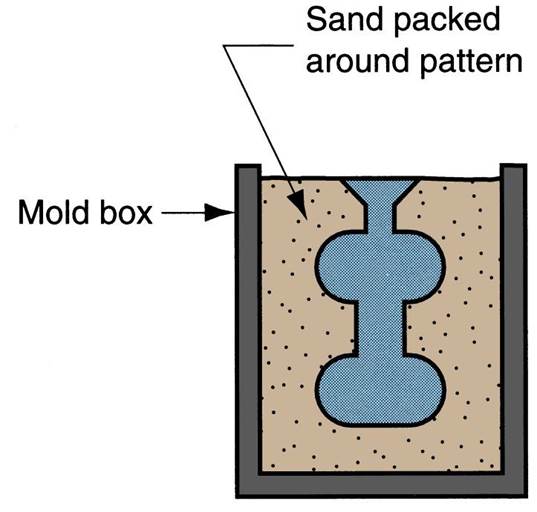

Figure Expanded polystyrene casting

process: (2) foam pattern is placed in mold box, and sand is compacted around

the pattern;

Figure

11.7 Expanded polystyrene casting

process: (3) molten metal is poured into the portion of the pattern that forms

the pouring cup and sprue.

As the metal enters the mold, the polystyrene foam is vaporized ahead of

the advancing liquid, thus the resulting mold cavity is filled.

Advantages

and Disadvantages

§Advantages of expanded polystyrene

process:

§Pattern

need not be removed from the mold

§Simplifies

and speeds mold‑making, because two mold halves are not required as in a

conventional green‑sand mold

§Disadvantages:

§A new

pattern is needed for every casting

§Economic

justification of the process is highly dependent on cost of producing patterns

Expanded

Polystyrene Process

§Applications:

§Mass

production of castings for automobile engines

§ Automated

and integrated manufacturing systems are used to

- Mold the polystyrene foam patterns and

then

- Feed them to the downstream casting

operation

Expanded polystyrene casting process: pattern of polystyrene is coated with refractory compound;

Figure Expanded polystyrene casting

process: (2) foam pattern is placed in mold box, and sand is compacted around

the pattern;

Figure

11.7 Expanded polystyrene casting

process: (3) molten metal is poured into the portion of the pattern that forms

the pouring cup and sprue.

As the metal enters the mold, the polystyrene foam is vaporized ahead of

the advancing liquid, thus the resulting mold cavity is filled.

Advantages and Disadvantages

§Advantages of expanded polystyrene

process:

§Pattern

need not be removed from the mold

§Simplifies

and speeds mold‑making, because two mold halves are not required as in a

conventional green‑sand mold

§Disadvantages:

§A new

pattern is needed for every casting

§Economic

justification of the process is highly dependent on cost of producing patterns

Expanded Polystyrene Process

§Applications:

§Mass

production of castings for automobile engines

§ Automated

and integrated manufacturing systems are used to

- Mold the polystyrene foam patterns and then

- Feed them to the downstream casting operation

ليست هناك تعليقات:

إرسال تعليق